In today’s fast-paced business environment, companies are constantly looking for ways to enhance efficiency, reduce costs, and ensure smooth operations. One area that has seen significant advancements in recent years is inventory optimization within the supply chain. With the growing complexity of global markets, increasing customer demands, and the pressures of maintaining lean operations, businesses are turning to technology—specifically artificial intelligence (AI)—to revolutionize inventory management and supply chain processes.

In this blog, we’ll explore how inventory optimization works, why it’s crucial for modern supply chains, and how AI is transforming the way companies manage inventory, predict demand, and reduce operational inefficiencies.

What is Inventory Optimization?

Inventory optimization refers to the practice of ensuring that the right amount of inventory is maintained at the right time in the right place, balancing costs while meeting customer demand. It’s not just about keeping a sufficient stock level; it’s about having the right mix of products, stored in the optimal locations, and replenished at the perfect time to prevent both stockouts and overstocking.

Effective inventory optimization aims to:

- Minimize Inventory Costs: By ensuring that inventory is neither excessive nor insufficient, businesses can cut down on holding costs, reduce storage space, and improve cash flow.

- Improve Service Levels: With accurate demand forecasting, companies can ensure that they have the necessary stock available when customers need it, thus avoiding stock outs that can lead to lost sales and customer dissatisfaction.

- Enhance Operational Efficiency: With optimized inventory, organizations can streamline their supply chain processes, reducing lead times, handling times, and minimizing the risk of errors in order fulfillment.

However, achieving these objectives is not easy, especially in today’s complex, globalized supply chains.

The Role of AI in Inventory Optimization

Artificial intelligence has become a game-changer in the field of inventory optimization. By using advanced algorithms, machine learning (ML), and big data analytics, AI can analyze vast amounts of information and make real-time decisions to optimize inventory levels. Here’s how AI is reshaping inventory management:

Demand Forecasting and Predictive Analytics

One of the most powerful capabilities of AI in inventory optimization is its ability to predict demand with incredible accuracy. Traditional forecasting methods typically rely on historical data and trend analysis, but AI can process not only historical data but also real-time information such as social media sentiment, weather patterns, economic indicators, and competitor actions.

AI-driven tools use machine learning models to identify patterns in demand that humans might miss. These models can factor in complex variables such as market conditions, customer preferences, and other external influences to generate more accurate demand forecasts. As a result, companies can make data-driven decisions about how much inventory to order and when, reducing the risk of stockouts and overstocking.

Inventory Tracking and Real-time Monitoring

AI-powered solutions can track inventory in real time, providing businesses with greater visibility into their stock levels across various locations, from warehouses to retail stores. Machine learning algorithms can monitor inventory movements, trigger restocking alerts when necessary, and even identify inefficiencies in the supply chain.

Real-time tracking also allows companies to detect discrepancies, such as missing or damaged products, and address them promptly, reducing the impact of these issues on inventory levels. This ensures that businesses can respond swiftly to disruptions and avoid stockouts or excess inventory.

Automated Replenishment

AI can automate the replenishment process by predicting when stock levels will run low and automatically triggering orders for restocking. This eliminates the need for manual inventory checks and ordering processes, reducing human error and saving valuable time. It also ensures that businesses always have the right products on hand, even during periods of high demand.

By optimizing order quantities and timing, AI helps companies maintain the ideal balance between supply and demand. Automated replenishment systems also help reduce the holding costs of inventory by avoiding the over-ordering of products that might sit on the shelf for too long.

Supply Chain Optimization

Inventory optimization isn’t just about managing stock; it’s also about optimizing the entire supply chain. AI can analyze supply chain data and identify inefficiencies, such as delays or bottlenecks in the production and delivery process. Machine learning models can assess supplier performance, shipping routes, and inventory levels across the entire network to make recommendations for improving efficiency.

AI-driven supply chain optimization tools can recommend better routes for transportation, suggest optimal order quantities, and even help manage supplier relationships to ensure timely deliveries. This reduces lead times, lowers costs, and helps organizations keep their inventory levels optimized.

Dynamic Pricing and Inventory Allocation

AI can also help businesses with dynamic pricing strategies. By analyzing demand fluctuations and market trends, AI can recommend optimal pricing for products to maximize sales and minimize excess inventory. This ensures that products are priced competitively, while still maintaining profitability.

Furthermore, AI can help optimize inventory allocation by ensuring that products are distributed to the right locations based on demand patterns. For instance, if a particular product is in high demand in a specific region, AI can prioritize inventory allocation to that region to ensure customers don’t face stockouts.

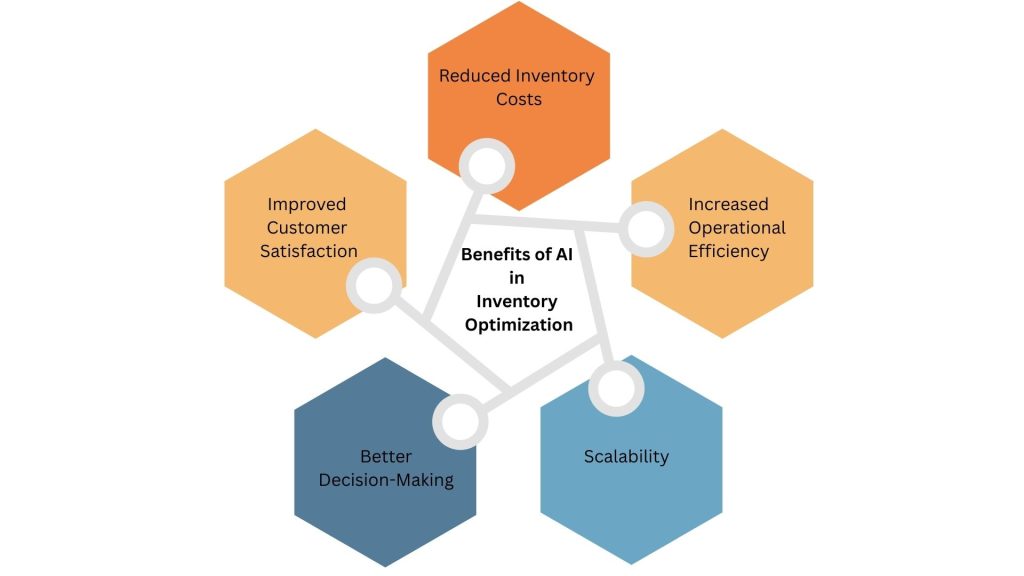

Benefits of AI in Inventory Optimization

The integration of AI into inventory optimization strategies offers several key benefits:

- Reduced Inventory Costs: By optimizing order quantities and reducing excess stock, companies can lower their inventory holding costs, which can be a significant portion of their overall expenses.

- Increased Operational Efficiency: AI reduces the need for manual inventory management, streamlines processes, and improves decision-making, resulting in more efficient operations.

- Improved Customer Satisfaction: With accurate demand forecasts, businesses can better meet customer needs, reducing stockouts and improving delivery times.

- Better Decision-Making: AI provides data-driven insights and recommendations, allowing businesses to make smarter decisions about inventory levels, ordering, and pricing strategies.

- Scalability: As businesses grow, AI systems can scale with them, handling larger datasets, more complex supply chains, and additional products without requiring significant manual intervention.

The Future of AI in Inventory Optimization

As AI technology continues to evolve, its impact on inventory optimization and supply chain management will only increase. The next frontier in AI-driven supply chains includes greater integration with the Internet of Things (IoT), where connected devices will provide even more granular insights into inventory levels and supply chain dynamics. Additionally, advances in AI-powered robotics and automation will further streamline warehouse operations, making them faster, more accurate, and cost-effective.

Moreover, AI will continue to evolve in its ability to adapt to real-time market shifts. With the growing volume of data available, AI systems will become more adept at handling unstructured data, allowing for even more precise predictions and insights. This will allow companies to maintain a truly agile supply chain that can respond to changes in demand, market conditions, and other external factors without delay.

The Pull Logic Agentic AI Framework encapsulates a cutting-edge AI-powered system designed to create self-regulating supply chains that continuously adapt to evolving market conditions. By leveraging advanced Agentic AI, ML and real-time analytics, this framework enhances supply chain agility, responsiveness, and efficiency. Organizations using this approach can seamlessly adjust to demand fluctuations, mitigate risks, and optimize inventory flow without manual intervention. Overview of Pull Logic’s Agentic Framework Agentic AI employs continuous self-correcting decision loops to refine inventory and replenishment strategies dynamically. By processing live data from sales, logistics, and market trends, it proactively optimizes stock levels, reducing both shortages and surpluses. This real-time intelligence ensures organizations maintain high product availability, minimize waste, and improve service levels. Additionally, Agentic AI-driven anomaly detection identifies potential disruptions before they impact operations, enabling preemptive corrective actions.

Conclusion

Inventory optimization is a critical component of modern supply chain management, and AI is emerging as the driving force behind more efficient, accurate, and cost-effective inventory practices. By leveraging AI for demand forecasting, real-time tracking, automated replenishment, and supply chain optimization, businesses can reduce costs, improve customer satisfaction, and stay competitive in today’s rapidly changing market.

As AI technology continues to improve, the future of inventory optimization holds great promise, offering companies the tools they need to manage their inventories more effectively and adapt to the ever-changing business landscape.

Traditional supply chain management depends on static models, periodic reviews, and reactive adjustments, often leading to inefficiencies and delays. In contrast, AI-driven supply chains harness predictive analytics, real-time monitoring, and automated decision-making to stay ahead of demand shifts. This proactive approach not only enhances forecasting accuracy but also enables organizations to respond dynamically to supply chain disruptions, ultimately driving better operational and financial outcomes. So, if you want to migrate from traditional inventory management to AI Agent driven inventory management, we can help you. Click here to schedule a call with one of our experts: https://pulllogic.com/contact/