Traditional inventory management systems, though reliable in the past, often fall short in providing the real-time accuracy, adaptability, and efficiency required by modern businesses. This is where Artificial Intelligence (AI) steps in, revolutionizing how inventory is monitored, managed, and optimized across industries.

Understanding Real-Time Inventory Tracking

Real-time inventory tracking refers to the continuous monitoring of inventory levels, movements, and conditions using digital tools. It ensures that businesses always have up-to-date information about what’s in stock, where it’s located, and how it’s moving across the supply chain. This information is crucial for avoiding running out of inventory, reducing excess inventory, improving order fulfillment, and enhancing overall customer satisfaction.

Historically, inventory tracking involved manual entry, barcode scanning, and periodic audits—methods prone to human error, delays, and inefficiencies. Today, AI-powered systems are redefining these processes, making inventory management more intelligent, predictive, and responsive.

How AI Enhances Real-Time Inventory Tracking

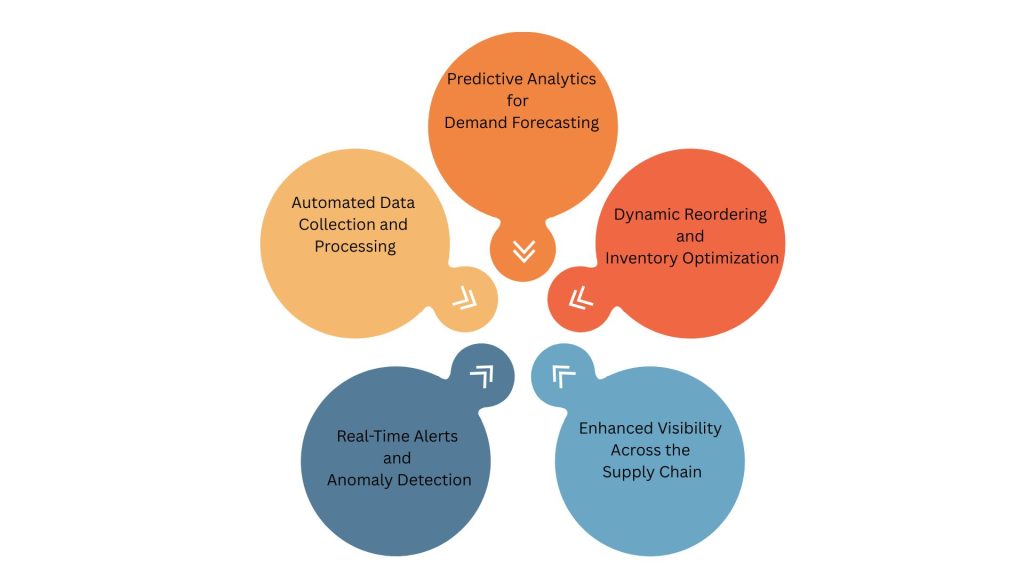

AI integrates several technologies—machine learning (ML), computer vision, natural language processing (NLP), and advanced analytics—to bring automation, intelligence, and accuracy to inventory tracking. Here are the key ways AI transforms this critical business function:

1. Predictive Analytics for Demand Forecasting

One of AI’s strongest capabilities is predictive analytics. AI systems analyze historical sales data, seasonal trends, consumer behavior, and even external factors like weather or economic indicators to forecast future inventory needs. This enables businesses to:

- Reduce inventory shortages by anticipating demand

- Avoid excessive inventory, which ties up capital and storage

- Plan procurement and production cycles more efficiently

Unlike traditional forecasting methods, AI can continuously learn and adapt as new data comes in, making predictions more accurate over time.

2. Automated Data Collection and Processing

AI streamlines data collection through IoT devices, smart sensors, and RFID (Radio Frequency Identification) tags. These tools feed real-time data into AI algorithms that monitor inventory levels and movements automatically. For example:

- Smart shelves can detect when products are running low

- RFID tags track the location and movement of goods throughout the warehouse or supply chain

- Computer vision systems scan products and packaging to verify inventory counts.

AI processes this data quickly and accurately, reducing the need for manual checks and minimizing human error.

3. Dynamic Reordering and Inventory Optimization

AI systems can automate the reordering process by setting intelligent reorder points based on real-time consumption patterns, lead times, and supplier reliability. This dynamic approach to inventory management ensures that:

- Orders are placed at the optimal time to avoid delays

- Safety stock levels are maintained efficiently

- Warehousing costs are minimized.

Retailers and manufacturers, in particular, benefit from this capability, as it ensures a more agile and responsive supply chain.

4. Real-Time Alerts and Anomaly Detection

With real-time tracking, businesses can receive instant alerts when inventory levels reach critical thresholds or when anomalies occur—such as unexpected stock depletion, misplaced items, or inventory shrinkage. AI can detect these issues through pattern recognition and anomaly detection models.

This proactive alert system enables businesses to take corrective actions immediately, preventing costly disruptions and maintaining operational efficiency.

5. Enhanced Visibility Across the Supply Chain

AI provides end-to-end visibility across the entire supply chain. Whether it’s a warehouse in Shanghai or a retail outlet in New York, AI systems can consolidate and analyze data from multiple sources to offer a unified view of inventory status. This level of transparency:

- Improves coordination among suppliers, logistics providers, and sales teams

- Reduces blind spots and bottlenecks in the supply chain

- Enables data-driven decision-making across departments.

Real-World Applications and Industry Examples

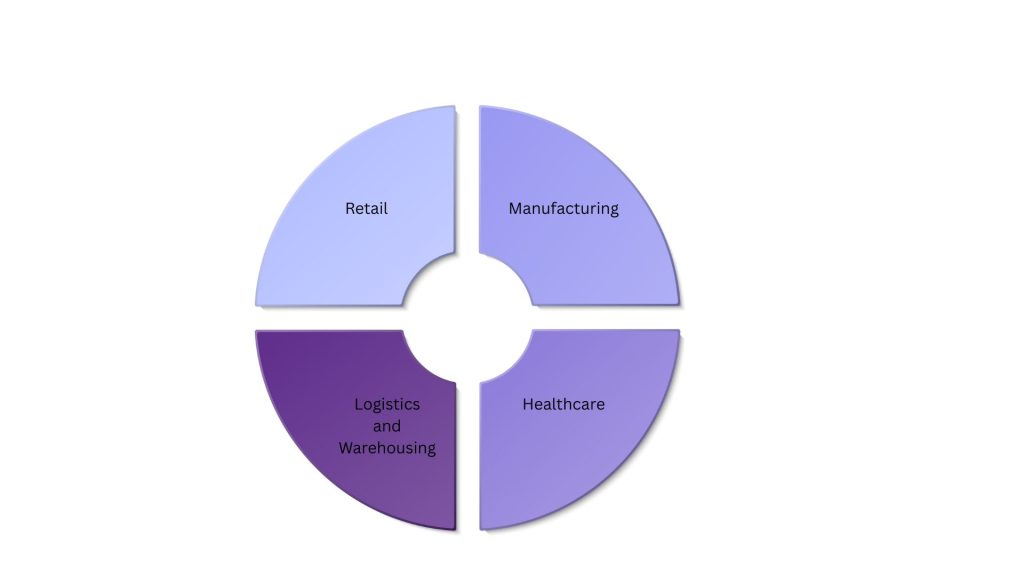

Retail

Retailers, such as Walmart and Amazon have been pioneers in using AI for inventory management. Their systems track inventory in real-time across thousands of locations, optimizing replenishment and reducing out-of-stock incidents. AI also supports personalized marketing by linking inventory levels with customer preferences and buying behavior.

Manufacturing

In manufacturing, AI helps maintain lean inventory levels without disrupting production. For example, AI monitors the usage of raw materials and components, predicts demand from downstream processes, and ensures timely procurement. This just-in-time inventory approach improves cash flow and operational efficiency.

Logistics and Warehousing

Logistics companies use AI-powered robotics and drones for inventory scanning and picking. These systems, combined with AI algorithms, optimize storage space, route planning, and order fulfillment. Real-time inventory tracking ensures accurate shipping and reduces returns due to order errors.

Healthcare

Hospitals and pharmaceutical companies leverage AI to track medical supplies, medications, and equipment. This not only ensures timely availability but also supports regulatory compliance, especially in handling perishable or controlled items.

Benefits of AI in Real-Time Inventory Tracking

The integration of AI into inventory tracking offers numerous advantages:

- Accuracy: Automated systems reduce human error and provide more reliable data.

- Efficiency: Processes that once took hours can now be completed in minutes.

- Cost Savings: By optimizing inventory levels, businesses reduce holding costs and avoid excess purchases.

- Scalability: AI systems can manage vast and complex inventories across multiple locations.

Customer Satisfaction: Faster fulfillment, better product availability, and fewer errors improve the customer experience.

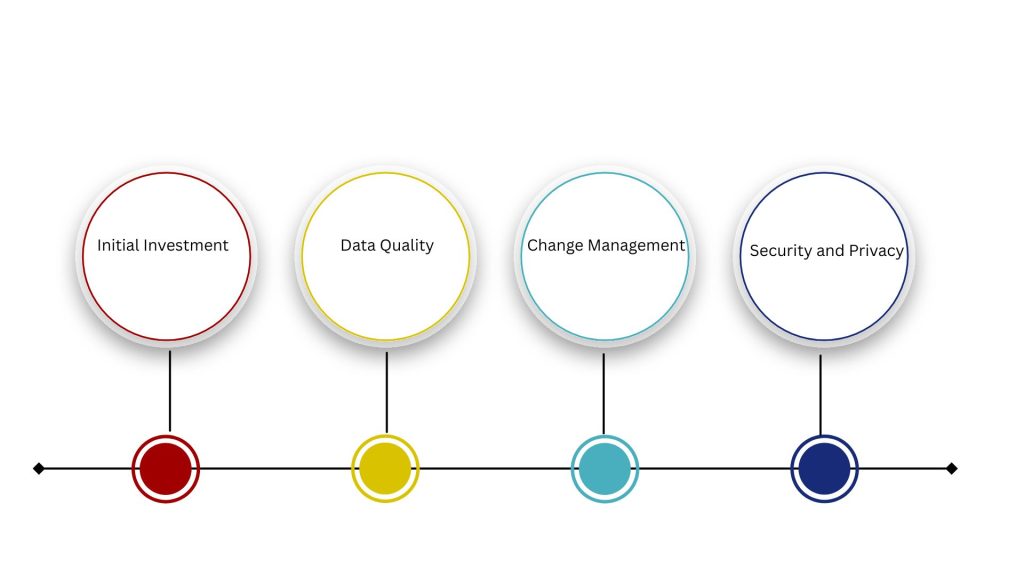

Challenges and Considerations

While the benefits are substantial, adopting AI in inventory tracking comes with its challenges:

- Initial Investment: Implementing AI solutions requires upfront capital for hardware, software, and integration.

- Data Quality: AI is only as good as the data it receives; poor data can lead to inaccurate predictions.

- Change Management: Employees need training to work alongside AI tools, and there may be resistance to change.

- Security and Privacy: With more data being collected and transmitted, ensuring its security is critical.

Despite these challenges, the long-term value of AI in inventory management outweighs the costs. Businesses that embrace AI now position themselves for sustainable growth and resilience in an increasingly digital world.

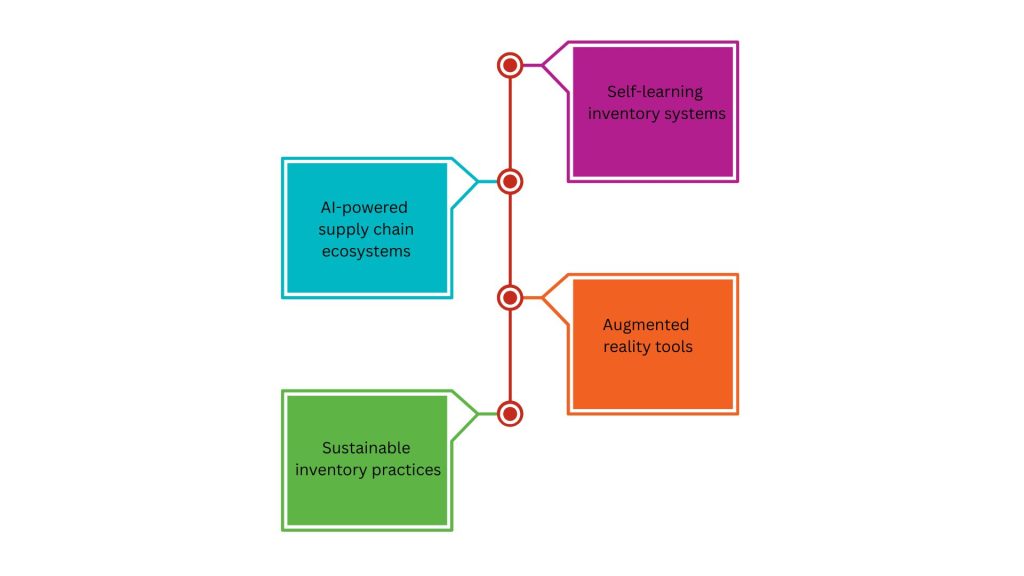

The Future of Inventory Management with AI

As AI technology continues to evolve, its applications in inventory tracking will become even more sophisticated. Future developments may include:

- Self-learning inventory systems that autonomously adapt to new patterns

- AI-powered supply chain ecosystems with fully integrated partners sharing real-time data

- Augmented reality tools for warehouse staff to visualize and interact with inventory data

- Sustainable inventory practices, with AI optimizing for minimal waste and environmental impact

In the near future, AI will not just be a tool in inventory tracking, it will be the standard.

Conclusion

Artificial Intelligence is transforming real-time inventory tracking from a static, reactive process into a dynamic, predictive, and highly efficient operation. By harnessing AI’s power, businesses gain visibility, agility, and control over their inventory like never before. While challenges remain, the trajectory is clear: AI is not just enhancing inventory tracking, it is redefining it.

Companies that invest in AI-driven inventory systems today will be the ones leading the market tomorrow. Whether you’re in retail, manufacturing, healthcare, or logistics, the time to embrace AI is now.

The Pull Logic Agentic AI Framework encapsulates a cutting-edge AI-powered system designed to create self-regulating supply chains that continuously adapt to evolving market conditions. By leveraging advanced Agentic AI, ML and real-time analytics, this framework enhances supply chain agility, responsiveness, and efficiency. Organizations using this approach can seamlessly adjust to demand fluctuations, mitigate risks, and optimize inventory flow without manual intervention. Agentic AI employs continuous self-correcting decision loops to refine inventory and replenishment strategies dynamically. By processing live data from sales, logistics, and market trends, it proactively optimizes stock levels, reducing both shortages and surpluses. This real-time intelligence ensures organizations maintain high product availability, minimize waste, and improve service levels. Additionally, Agentic AI-driven anomaly detection identifies potential disruptions before they impact operations, enabling preemptive corrective actions. So, if you too want to fix your real-time inventory tracking woes then schedule a meeting here: https://pulllogic.com/contact/